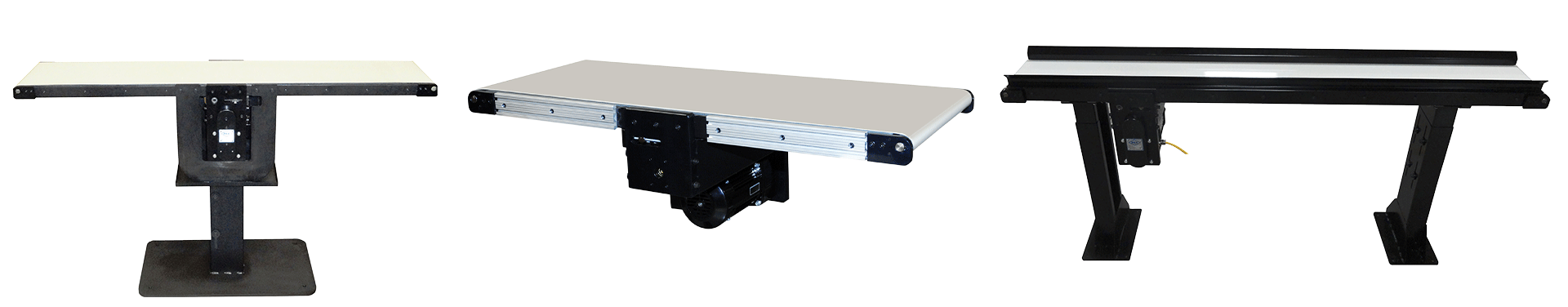

Center Drive Conveyors

This rugged conveyor can be configured and customized as required to meet a wide variety of applications.

- Height of Conveyor Ends: 2.1″

- Motor located below the conveyor

- Can be utilized as a parts diverter

Overview

Overview

This rugged conveyor can be configured and customized as required to meet a wide variety of applications. The motor, drive pulley, and belt tensioning for this conveyor are located beneath the conveyor, which keeps the top of the conveyor unobstructed. The motor’s exact location can be specified by the customer at the time of order.

Popular options for this conveyor include:

- Adjustable stands

- Side Rails

- Adjustable speed

- Reversible Drive

- Parts Dividers

- Extruded Aluminum Side Rails

Conveyor Belt

Conveyor Belt

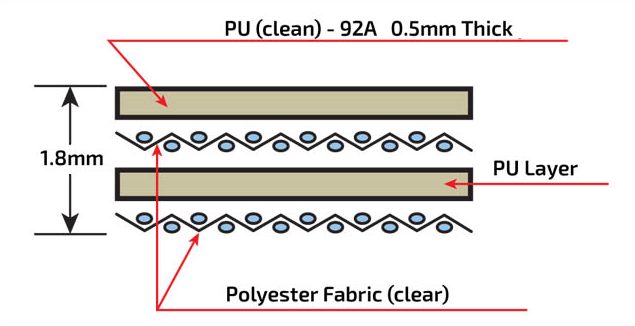

2 Ply Mono-Filament, Urethane belt

This is the standard belt for the CD conveyor. This smooth, white belt is oil resistant and is comprised of 2 layers of clear polyurethane and 2 layers of urethane-coated polyester material, which combine for a total thickness of 1.8 mm. This belt is connected with stainless steel lacing and a pin.

Custom Belts

Contact Pax in regards to endless belts or belts made from alternate materials.

Speeds & Dimensions

Speeds & Dimensions

Standard Fixed Belt Speeds: 29, 34, 40, 46, 54, 69, 80 & 92 feet/min.

Standard Variable Belt Speed: 25 to 90 feet/min.

Custom Belt Speeds: Contact Pax for higher or custom speeds.

Length: Standard lengths are 24” to 120” (Refer to the below sketch)

| Model Width | STANDARD CONVEYOR WIDTHS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4″ | 5″ | 6″ | 7″ | 8″ | 9″ | 10″ | 12″ | 14″ | 16″ | 18″ | 20″ | |

| Belt Width (A) | 2.6″ | 3.6″ | 4.6″ | 5.6″ | 6.6″ | 7.6″ | 8.6″ | 10.6″ | 12.6″ | 14.6″ | 16.6″ | 18.6″ |

| Tension End Width (B) | 3.95″ | 4.95″ | 5.95″ | 6.95″ | 7.95″ | 8.95″ | 9.95″ | 11.95″ | 13.95″ | 15.95″ | 17.95″ | 19.95″ |

Popular Options

Popular Options

Side Rails

The CD conveyor can be provided without side rails or with side rails of various heights. The standard side rail height is 2” alternate heights and custom configurations are available.

Adjustable Support Stand with Pivoting Top Plate:

The stand will bolt to a plate that will be attached to the bottom of the conveyor. By loosening these bolts, the plate can be pivoted to hold the conveyor at an angle. The base of the stand is 24” wide by 8” deep and the stand is designed to sit on and/or be bolted to the floor. The stand is painted black.

Height Ranges:

| Pax Part Number | Height from Floor to Bottom of Conveyor Tray |

Height from Floor to Top of Conveyor Belt |

||

|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | |

| 500-5440-0 | 16.0” | 24.0” | 18.1” | 26.1” |

| 500-5441-0 | 21.0” | 28.0” | 23.1” | 30.1” |

| 500-5442-0 | 24.0” | 36.0” | 26.1” | 38.1” |

| 500-5443-0 | 32.0” | 44.0” | 34.1” | 46.1” |

| 500-5444-0 | 36.0” | 56.0” | 38.1” | 58.1” |

Adjustable, Pivoting, Support Stand with Casters:

The stand consists of two adjustable legs attached to a common base plate, which will have FOUR, locking, swivel-type casters. Each leg is attached to the bottom of the conveyor by a separate top plate. These top plates can be pivoted, (by loosening and retightening their bolts), which allows the stand to support the conveyor at an angle if desired.

The conveyor motor will be located between the two adjustable legs and, if the conveyor has adjustable speed, its VFD will be located on the lower portion of one of the adjustable legs. The base of the stand is 24” wide and 48” long. The stand is painted black.

Height Ranges:

| Height from Floor to Bottom of Conveyor Tray |

Height from Floor to Top of Conveyor Belt |

||

|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum |

| 20.7” | 28.7” | 22.8” | 30.8” |

| 25.7” | 32.7” | 27.8” | 34.8” |

| 28.7” | 40.7” | 30.8” | 42.8” |

| 36.7” | 48.7” | 38.8” | 50.8” |

| 40.7” | 60.7” | 42.8” | 62.8” |

Variable Speed Motor & Control:

With this option, the standard conveyor motor is replaced with a 3-phase motor and a Variable Frequency Drive (VFD). is utilized to start and stop the conveyor.

Arrangements for Custom Mounting

Extruded Aluminum Attached to Side Rails:

To provide flexibility in mounting, extruded aluminum with two T-slot grooves will be fixed to the conveyor side rails. Contact Pax Products for pricing.

Clinch Nuts Added to Conveyor Sides

As an alternative to the extruded aluminum rails described above, nuts with 1/4” tapped thread can be pressed to fit into each side of the conveyor.