V-Series System

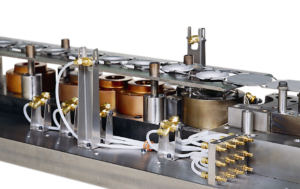

Systems have independently programmable spray lines and can spray lubricants with viscosities up to 100 SUS, which is equivalent to most water-soluble type lubricants that are mixed with 3 or more parts water to 1 part lube. Systems can be provided with or without a reservoir, with or without control, and can be arranged for dual lube applications.

Reduction of Die Lubricant Usage – By applying only the lubricant you need only where you need it, and by also collecting excess lubricant and draining it back into the Pax system reservoir, many Pax customers have reduced their lubricant usage by over 50%.

Increased Production, Tooling Life, and Part Quality – Proper lubrication can greatly reduce the amount of heat and friction that occur on both the part and the tool, which can increase tooling life and allow higher production speeds with improved part quality.

Improved Working Conditions – A clean environment improves workers’ attitudes. The Pax system applies die lubricant to only the defined critical areas – not to the side of the press, the feeder, or the floor.

System Overview

System Overview

Airless Spray

No air is mixed with the pressurized lubricant supplied to the spray lines. This results in an “airless” spray that better adheres to the material and creates much less air-borne lubrication than air-atomized sprays.

Capable of Spraying Fluids of Various Viscosities

Air pressure can be regulated as required for different viscosity fluids. For fluids with a viscosity higher than 100 SUS, it is important to identify the supplier and viscosity of the fluid so Pax may provide the most efficient configuration for the application.

Independently Programmable Spray Lines

Each solenoid valve can be independently controlled and may be programmed to spray at different intervals, and for different durations (minimum 20 milli-seconds) during a press cycle. Pax’s optional PLC control or an alternate, existing control be utilized to operate the system.

No Priming Issues

A large diaphragm pump supplies filtered fluid to the individual spray lines at pressures up to 100 psi.

Reduced Maintenance

The system requires no airline lubrication, requires no dynamic seals, and no accumulators.

Models with Reservoirs

Models with Reservoirs

| Model Numbers | ||||||

|---|---|---|---|---|---|---|

| V5-5 | V5-15 | V10-15 | V5-30 | V10-30 | V15-30 | |

| Number of Independent Spray Lines | 5 | 5 | 10 | 5 | 10 | 15 |

| Reservoir Capacity Gallons (Liters) | 5 | 15 | 30 | |||

| Size (Width x Depth x Height) | 13.7” x 13.7” x 36.1” (348 x 348 x 917 mm) |

16.3” x 16.3” x 47.9” (414 x 414 x 1215 mm) |

22.2” x 22.2” x 47.6” (564 x 564 x 1209 mm) |

|||

| Operation Air Pressure | 30 to 100 psi (205 to 860 kilopascal) | |||||

| Voltage | 115 VAC/60 HZ and 24 VDC are Standard | |||||

Tankless Models

Tankless Models

Pax tankless systems can be utilized with central lubrication supply systems or to spray lubrication directly out of the drum or other customer-supplied reservoirs. Depending on the application, the tankless units can be provided with the optional diaphragm supply pump and one of the optional filter assemblies listed on the following page; or the units can be supplied without a pump or filter assembly for central lubrication systems.

| Model Numbers | |||

|---|---|---|---|

| V5T | V10T | V15T | |

| Number of Independent Spray Lines | 5 | 10 | 15 |

| Operation Air Pressure | 30 to 100 psi (205 to 860 kilopascal) | ||

| Voltage | 115 VAC/60 HZ and 24 VDC are Standard | ||

Model V5M

The Pax Model V5M may be utilized for central lube system applications. This assembly includes 5 solenoid valves that can be independently controlled and may be programmed to spray at different intervals and for different durations during a press cycle. Either Pax’s control or a customer-supplied control can be utilized to control the individual solenoids on this unit.

Dual Lube Systems

Dual Lube Systems

Dual Lube Systems

These systems allow the user to select between two different lubricants, which are stored in separate reservoirs. The systems can utilize either a V5T, V10T, or V15T tankless system in conjunction with any of Pax’s standard reservoirs. Lube selection, which reservoir the system will draw from, can be done via either manual or electronic valves.

Popular System Options

Popular V-Series System Options

Controller Interface (P/N 00-1406-21)

This PLC-based interface provides the capability to individually control each spray line. This includes setting if, when, and how long each line sprays after an input signal is received. An embedded counter function allows the operator to determine if a line is to spray every cycle or only after a pre-determined number of cycles. The individual settings for 112 different jobs (numbered 1 through 112) can be saved and the stored jobs are password protected to prevent unauthorized changes. This operator-friendly, full-color control also includes a manual mode through which the operator can cycle the current job or can spray all lines simultaneously to purge the system. Note: This interface is in the ENGLISH language.

Power Cord and Plug

For the standard 115 V system, a nine-foot power cord with a three-prong plug can be provided.

Air Agitation

For use with water-soluble lubricants to assure the lubricating medium remains in suspension. A needle valve regulates the amount of air applied to the lubricant reservoir.

Low-Level Float

The float switch is designed to connect to the press’ top stop circuit to prevent running the dies dry.

Automatic Refill System:

This system consists of three separate components, listed below, that work in conjunction to maintain fluid in the reservoir.

Automatic Refill Solenoid Valve

This valve mounts on the rear of the lube system reservoir and is controlled by the float switches to maintain an adequate supply of lubricant to the system. The valve has a 3/8” NPT (female thread) to which the customer needs to connect their pressurized, lubricant supply. Note: A constant, pressurized lubricant supply must be provided to the valve.

Automatic Refill Floats

A dual float switch system that works in conjunction with the auto refill solenoid valve. These switches open the valve when the fluid is at a level where it needs to be refilled and they close the valve when the reservoir is full.

Low Level Float

This additional float switch detects if the lubrication level in the reservoir goes significantly below the refill level. By interfacing this with the press’s top stop circuit, the customer can stop the press before the reservoir runs out of fluid.

Reservoir Strainer For 5-gallon, 15-gallon & 30 Gallon Systems

This strainer adapts to the lube system reservoir to prevent larger particles from entering the reservoir when fluid is poured into the system. Note: Fluid that enters the system via the return line does not pass through this strainer.

Pressure Monitoring Sensors for Spray Lines, (PN 05-1444-30):

This Sensor Assembly is an electronic pressure monitor that allows for the monitoring of a specific spray line of your lubrication system via die protection or PLC integration.

By monitoring the changes in pressure during each spray cycle, the sensor can determine if that line is spraying each cycle. During a spray cycle, the pressure in the spray line rises quickly as fluid is dispensed through the nozzle. After a point in time, the pressure in the spray line reaches a maximum and begins and drops again. When set correctly, the set point pressure of this sensor is triggered when the pressure initially rises during a spray cycle, and the reset point pressure on this sensor is triggered when the pressure decreases. The change of output provided by the sensor as a result of these pressure changes can then be monitored by the customer.

The pressure settings for the switching output of the sensor are controlled via the set and reset point, which is manually set by the user utilizing the orange dials on the sensor. Each Pax spray nozzle has a unique line pressure that is maintained between sprays. The pressure switch must have the set point and reset point above this baseline pressure. Values for the set point, reset point and baseline pressure are subject to each customer’s particular application, cycle speed, and hardware configuration. The switch is capable of monitoring the Pax standard nozzles, high-pressure nozzles, and piston nozzles assemblies. The high-pressure piston requires a higher pressure range and is not suited to this sensor.

The pressure switch utilized is a PNP-type sensor that requires a 24 VDC power supply and it provides both normally open and normally closed outputs. Note: It is the customer’s responsibility to provide power to each sensor and to integrate the sensor outputs with either their die protection system or with a PLC as required. Pax will supply a 5-meter long, M12, 4-pin connector cable with each sensor for the customer to utilize for this integration.

V-Series Spray Nozzles

V-Series Spray Nozzles

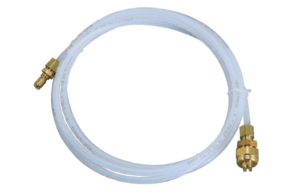

Standard Nozzle for V-Series Systems & Pax Original Style Systems

Std Nozzle with 1/8″ NPT

FEMALE Threads

Std Nozzle with 1/8″ NPT

MALE Threads

Std Nozzle with Compression

sleeve and nut for 1/4″ Tubing

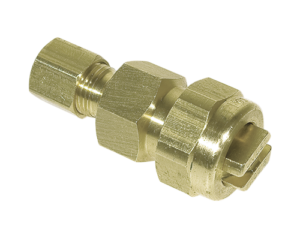

Nozzle Components

A: Nozzle Body

B: Check Valve Strainer

C: Spray Tip

D: Tip Retainer

Pre-Pressurized Spray Assemblies

Magnetic Base Spray Assembly with Standard Nozzle (06-3112-31)

The magnetic base provides flexibility for positioning the assembly as required and the rigid clamping and spraying assembly assures that the unit remains where it is positioned. The assembly includes a 250 lb. pull magnet with steel post, clamp assembly, stainless steel tube, female nozzle assembly with choice of spray tip, quick connect male plug, and 8′ of ¼” hard, (nylon), tubing.

Flextube Magnetic Base Spray with Standard Nozzle (06-3016-30)

The flextube assembly provides ultimate flexibility for positioning the spray nozzle, however, it can also be more easily moved out of position than either the magnetic base assembly or the bracket mount assembly. One flextube assembly includes a 250 lb. magnet w/bracket and release lever, flextube segments, 8’ of ¼” hard, (nylon), tubing, tubing nozzle assembly, and male plug.

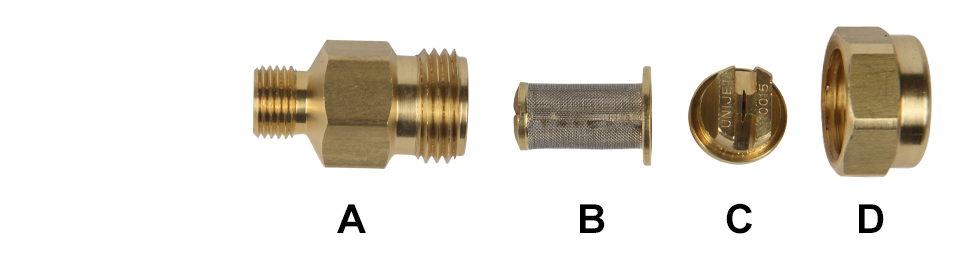

Spray Line Assemblies with Standard Nozzle, (06-3012-31)

This 8’ long, ¼” spray line has a quick connect male plug on one end, (to connect to the Pax distribution pumps), and a spray nozzle (including nozzle body, check valve, tip retainer, and choice of spray tip) on the other end. The customer is responsible for determining the mounting arrangement.

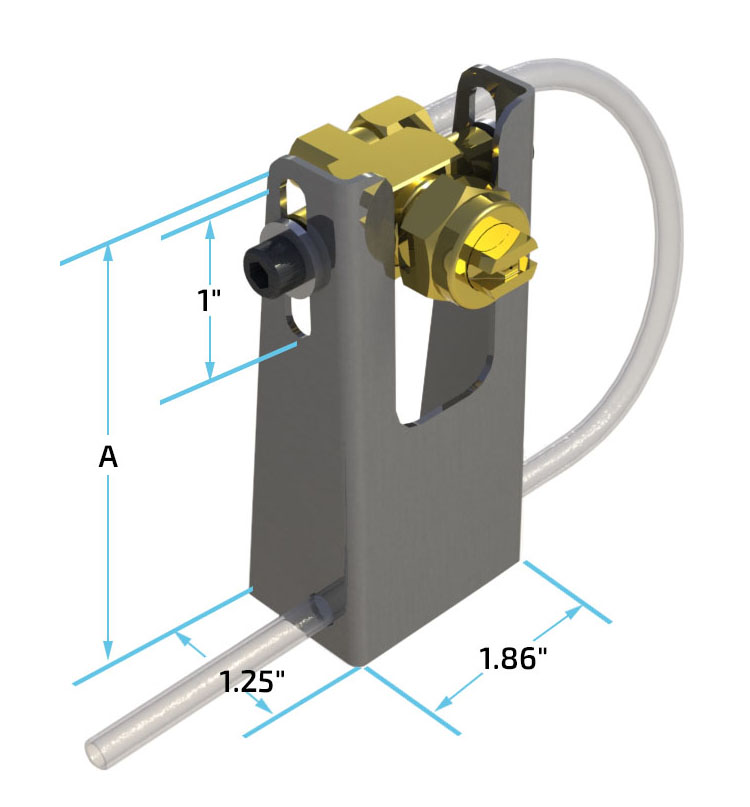

Bracket Mount Spray Assemblies for Pax V-Series & Original Style Systems

Pax bracket assemblies are the ideal way of permanently mounting spray assemblies. The spray angle can be adjusted by simply rotating either the nozzle and/or the bracket and the vertical height of the nozzle can be adjusted by moving the nozzle within the bracket slot. Once the position of the assembly is finalized, it is locked in place by tightening the bracket screws.

Assemblies include stainless steel bracket, spray nozzle, choice of spray tip, tip retainer, check valve, 1/8″ male elbow, mounting screw, and stainless steel washer. (Requires ¼-20 tapped holes for mounting).

| Bracket Size | A | Part Numbers |

|---|---|---|

| 1″ to 2″ | 2.45″ | 06-3109-30 |

| 2″ to 3″ | 3.45″ | 06-3110-30 |

| 3″ to 4″ | 4.45″ | 06-3111-30 |

| 4″ to 5″ | 5.45″ | 06-3112-30 |

| 5″ to 6″ | 6.45″ | 06-3113-30 |

| 6″ to 7″ | 7.45″ | 06-3114-30 |

| 7″ to 8″ | 8.45″ | 06-3115-30 |

| 8″ to 9″ | 9.45″ | 06-3116-30 |

| 9″ to 10″ | 10.45″ | 06-3117-30 |

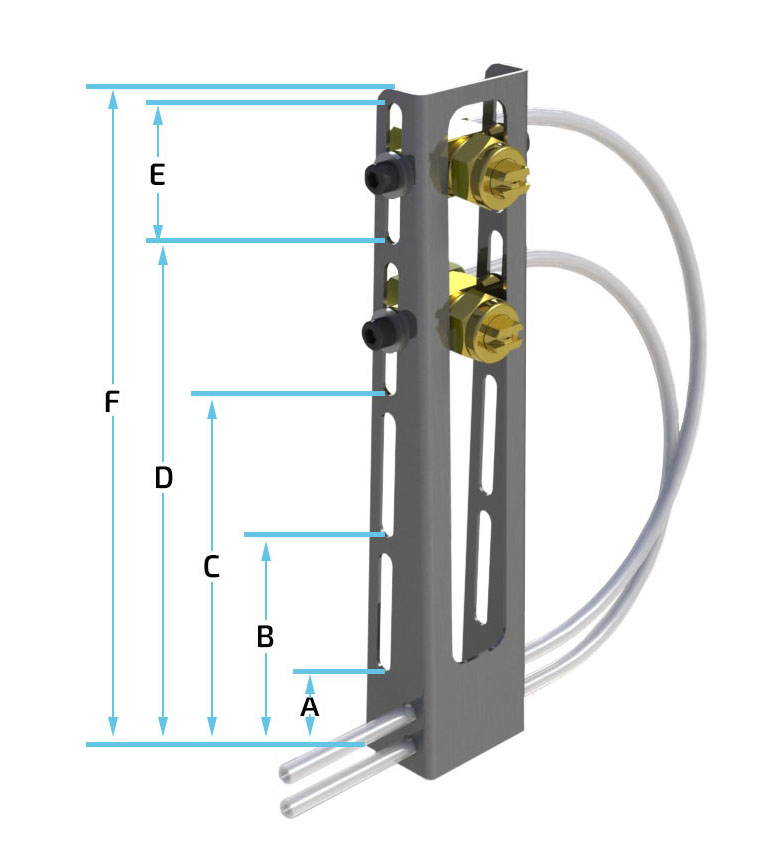

Multi-Nozzle Bracket Mount Assembly for Pax V-Series & Original Style Systems

Includes stainless steel bracket, a mounting screw, a stainless-steel washer, and two of each of the following: spray nozzle, choice of spray tip retainer, check valve, and 1/8″ male elbow. (Requires ¼-20 tapped holes for mounting).

| Bracket Size | Bracket Dimensions | Pax Part Numbers | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||

| 5″ | 1.5″ | 3.5″ | N/A | N/A | 1.5″ | 5.3″ | 06-3126-30 |

| 6″ | 1.6″ | 3.2″ | 4.9″ | N/A | 1.1″ | 6.3″ | 06-3127-30 |

| 7″ | 1.5″ | 3.5″ | 5.5″ | N/A | 1.5″ | 7.3″ | 06-3128-30 |

| 8″ | 1.7″ | 4.0″ | 6.2″ | N/A | 1.8″ | 8.3″ | 06-3129-30 |

| 9″ | 1.5″ | 3.5″ | 5.5″ | 7.5″ | 1.5″ | 9.3″ | 06-3130-30 |

| 10″ | 1.5″ | 3.7″ | 6.0″ | 8.2″ | 1.8″ | 10.3″ | 06-3131-30 |

Spray Tips (contact Pax for additional tip options)

| Style | Type | Pattern Size | Part No. |

|---|---|---|---|

| Flat | 25° | 1.50″ x 3.50″ | 06-0973-20 |

| Flat | 50° | 2.00″ x 5.75″ | 06-0951-20 |

| Flat | 65° | 2.00″ x 7.50″ | 06-1908-20 |

| Flat | 80° | 2.00″ x 9.50″ | 06-0950-20 |

| Flat | 95° | 2.25″ x 12.00″ | 06-1909-20 |

| Flat | 110° | 2.50″ x 14.00″ | 06-0952-20 |

| Deflected | .041″ Orifice | 4.00″ x 18.00″ | 06-0956-20 |

| Cone | .020″ Orifice | 3.50″ Diameter | 06-0958-20 |

| Cone | .024″ Orifice | 4.25″ Diameter | 06-0953-20 |

| Cone | .030″ Orifice | 5.50″ Diameter | 06-0959-20 |

Note: A low-viscosity (Tellus #10) lubricant was used to obtain the pattern sizes described. The tips were placed in the vertical position and held 6″ from the surface with an air pressure setting on the FRL of 35 psi. Pattern sizes may vary depending on lubricant viscosity and air pressure setting.

Fittings

Swivel Adapter

1/8″ MNPT x 1/8″ FNPT

4-Port Stackable Die Manifold

1/8″ FNPT Stackable Manifold

Manifold Assembly

(Provided Unassembled)

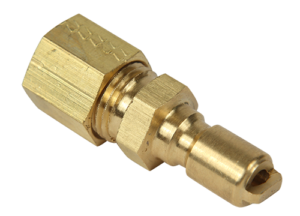

1/4″ Compression

QC Plug

1/8″ MNPT

QC Plug

1/8″ MNPT QC Plug

W/ Valve Core

1/8” FNPT

QC Plug

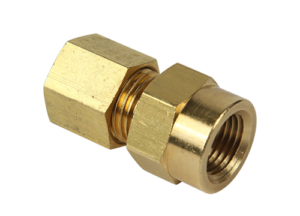

1/4″ x 1/8″

FNPT Compression

1/4″ x 1/8″

MNPT

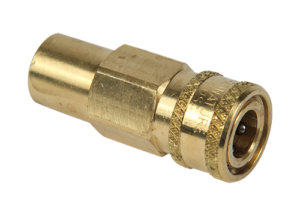

1/8″ FNPT x QC

Coupling

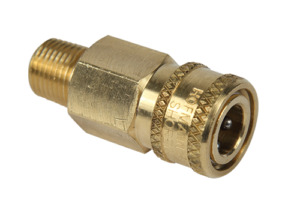

1/8″ MNPT x QC

Coupling

1/4″ Compression x

1/8″ MNPT

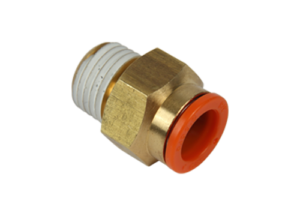

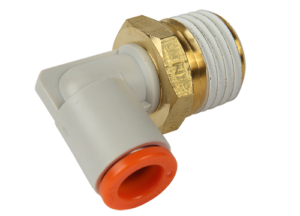

Push To Connect

Straight

Adapter

Fitting

Tip

Retainer

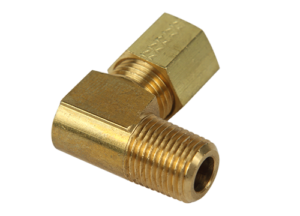

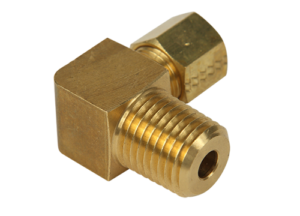

Elbow Compression

Fitting

Compression Sleeve

1/4″ Tubing

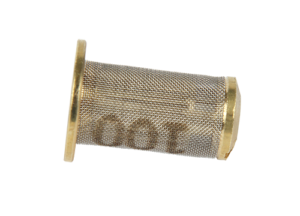

Standard Check Valve for

V-Series and Original Series

H.P. Check Valve for

Pre-Pressurized Systems

Push To

Connect

Push To

Connect

Push To

Connect

Push To

Connect

MNPT = Male Pipe Thread

FNPT = Female Pipe Thread

QC = Quick Connect

Note: Other fittings are available upon request.