About Us

Pax Products is a manufacturer of ancillary pressroom equipment including Spray and Roller type lubrication systems, Press Door safety barriers, part and scrap Belt Conveyors, and Oscillating Conveyors for individual machines and for complete plant scrap removal.

Pax Products equipment is used by manufacturers and metal stampers throughout the world and also by our sister company, Pax Machine Works, which is how we got our slogan — “Designed for Stampers by Stampers.”

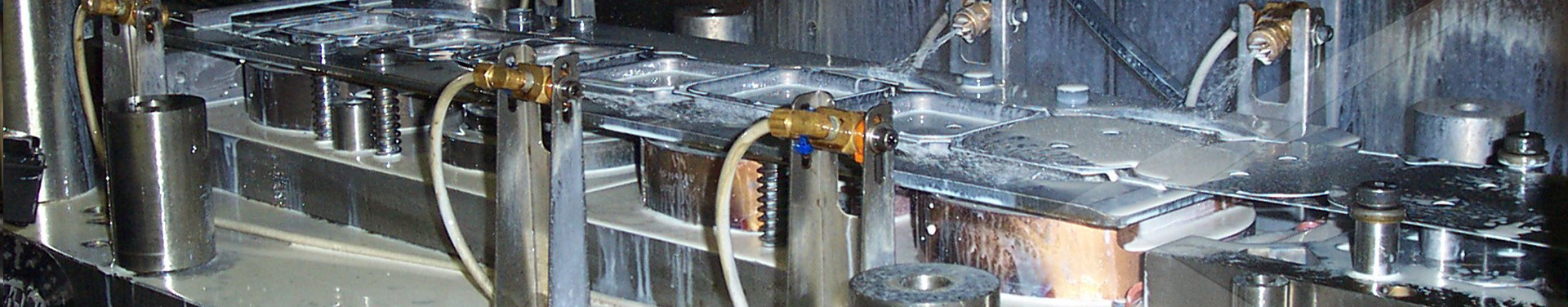

Since 1980, Pax Lubrication Systems has been helping stampers increase production speeds, reduce lubrication usage, extend die life and improve part quality. Whether you are lubricating the stock before the die or doing in-die lubrication with either a heavy draw lube or a light viscosity lube, Pax can provide a lubrication system to meet most stamper’s needs.

Pax Press Doors provide the safety of a hard barrier while providing a method of containing and controlling die lubricants and also ergonomic access to the press. Vertically sliding, swing-out, powered, and acoustical designs are available.

Pax Belt Conveyors were each developed to provide the user with a specific advantage:

The Pax Low Profile Conveyor was developed for on-bolster, under-die, parts and scrap removal. Its low height allows it to fit where other conveyors can’t and its ability to withstand lubrication allows it to survive in the harsh metal stamping environment. The optional stopped belt sensor provides the ability to top-stop the press in the event of a belt jam.

Pax CD Conveyor is more customizable than the above Low Profile Conveyor. The CD conveyor can be utilized as a part-out and ascrap-out conveyor and can also be configured to be utilized as a parts diverter, which automatically reverses direction to transfer parts to a different bin when the first bin has reached capacity.

Pax Drum Motor Conveyors were developed for part removal and transfer. These rugged conveyors utilize a motorized pulley that is ideal for dirty environments and also eliminates clearance issues that can be created with external motors. These conveyors can be customized to include cantilevered designs, powered vertical and horizontal movement, powered tilt functions, servo-type positioning, extremely high belt speeds, as well as many other custom features.

The Pax EGD and EGDF Oscillating (shaker type) Conveyors were developed to perform part and scrap removal at conveying speeds up to 25 fpm. The patented, high torque, low maintenance, electrically driven, elliptical geared design drives the attached tray(s). The EGD designs are typically connected directly to a single machine and utilize multiple trays, which are attached to EGD unit via quick-connect brackets, to remove parts and scrap. The EGDF design is a single tray design. Smaller EGDF units are typically located below a single machining center or laser while larger EGDF systems can be utilized for below-ground scrap removal from an entire plant.