EGD, Multi-Tray Conveyors

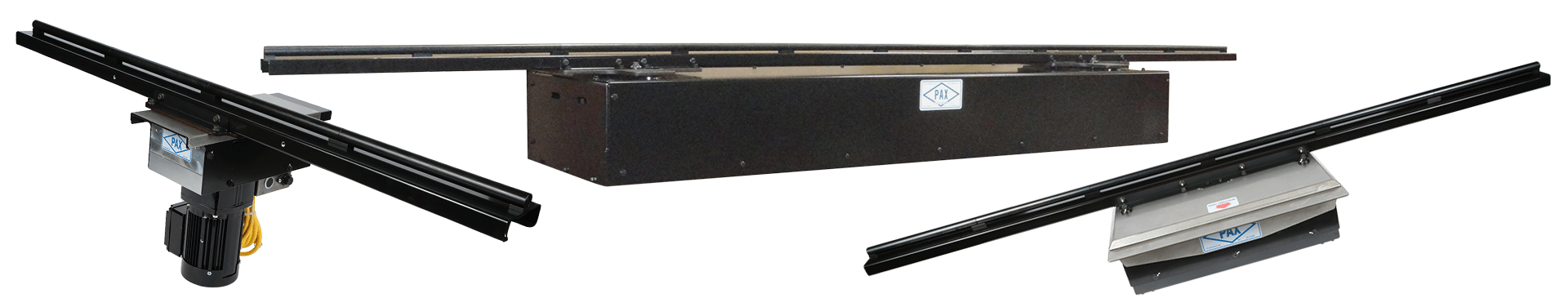

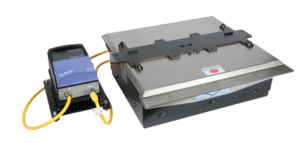

The patented Pax EGD conveyor is an electrically driven, oscillating type conveyor that utilizes a motorized, elliptical gear drive (EGD). Utilizing elliptical gears in a sealed oil bath provides an extremely reliable drive and a high conveying speed at lower RPMs.

The EGD conveyor is currently available in three sizes, which are rated based on the total tray weight (this does not include the weight of the parts and scrap on the trays).

- EGD-50: can hold up to 50 lbs of tray weight PLUS parts

- EGD-125: can hold up to 125 lbs of tray weight PLUS parts

- EGD-250: can hold up to 250 lbs of tray weight PLUS parts

Key features of this conveyor include:

- No Air Consumptions

- Quick Snap-On Tray Design

- No Springs or dynamic seals

Features

Features

Quick and Easy Tray Attachment

Tray brackets simply snap in place over the round portion of the crossbar without the use of tools. The machined, Acetal brackets bolt to the side of the conveyor tray can rotate on the crossbar if the tray needs to run on a slight angle.

Electrically Driven, Elliptical Geared Drive

The elliptical drive gears are bathed in oil inside of a sealed gearbox. This arrangement minimizes the reverse inertia effects that create issues for many other conveyor designs.

No Air Consumption

The EGD conveyor is electrically driven which means that it does not have the high operating costs and ongoing maintenance issues that are associated with many air-driven conveyors.

Specifications

Specifications

| Conveyor Model | EGD-50 | EGD-125 | EGD-250-48 | EGD-250-72 |

|---|---|---|---|---|

| Tray Weight Capacity | 50 Lbs. | 125 Lbs. | 250 Lbs. | 250 Lbs. |

| Part/Scrap Capacity | 100 Lbs. | 250 Lbs. | 500 Lbs. | 500 Lbs. |

| Cross Bar Lengths | 1′ to 5′ In 6″ Increments |

2′ to 10′ In 6″ Increments |

4′ to 12′ In 6″ Increments |

6′ to 16′ In 6″ Increments |

| Alternate Lengths and/or Alternate Cross Bar Designs Are Available. Contact Pax For Details. | ||||

| Unit Dimensions | 16.5″H x 6.7″W x 15.6″D | 9.4″H x 20″W x 15″D | 11.6″H x 49″W x 17.5″D | 12″H x 72″W x 18″D |

| Note: Above Dimensions Do Not Include the Width of the Crossbar. | ||||

| Unit Weight | 50 Lbs. | 95 Lbs. | 440 Lbs. | 700 Lbs. |

| Motor Size | 1/6 HP Gear Motor | 3/8 HP Gear Motor | 3/4 HP Gear Motor | 3/4 HP Gear Motor |

| Control Type | Push Button On/Off Switch | Externally Mounted Control is Utilized for On/Off | ||

| Drive Location | The bar is Driven in the Center, Between the Four, Widely Spaced, Linear Bearings to Maximize Bearings Life. |

Each Set of Bearings is Directly Driven in Order To Further Resist Off-Center Loading and Increase Bearing Life. |

||

| Conveying Speed | Fixed Conveying Speed. Parts May Be Conveyed Up to 25 Feet Per Minute Depending On the Type of Part Being Conveyed and the Type and Cleanliness of the Tray. |

|||

| Voltage Input | Standard Input Voltage is 120VAC, Single Phase, 60Hz, But Alternate Voltages Are Available. | |||

EGD-50 Options, Pictures & Drawings

EGD-50 Options, Pictures & Drawings

Optional, Quick Release Arm Arrangement:

To provide increased access to the press, this quick-release option allows the operator to simply lift the arm, (crossbar), off of the unit and to re-install the arm by simply placing it back on the top of the unit. No tools are required to remove or replace the arm.

T- Slot Type Mounting Brackets:

Bracket bolts to the bottom of the EGD-50 and is arranged to attach to standard T-slots. Standard brackets are based on a vertical mounting surface of 5.25”, (this is the height of the vertical plate on the bracket).

Brackets are available for different T-slot sizes and spacing as shown below, (contact Pax for detailed dimensions of the required bracket).

EGD-050-6190-0: ¾” T-Slots on 6” spacing, bar widths of A = 0.72” and B = 1.38″.

EGD-050-6192-0: ¾” T-Slots on 12” spacing, bar widths of A = 0.72” and B = 1.38”.

EGD-050-6191-0: 1” T-Slots on 6” spacing, bar widths of A = 0.97” and B = 1.50”.

EGD-050-6193-0: 1” T-Slots on 12” spacing, bar widths of A = 0.97” and B = 1.50”.

Vertical Face Mounting Bracket (PN EGD-050-6194-0):

The bracket bolts to the bottom of the EGD-50 and is arranged to be bolted to a vertical surface (such as the face of a bolster plate). Standard brackets are based on a vertical mounting surface of 5.25”, (this is the height of the vertical plate on the bracket). Contact Pax for detailed dimensions.

Option of Utilizing an Extruded Aluminum Cross Bar in Place of Pax’s Standard Cross Bar:

For customers who have standardized extruded aluminum type cross bars, an extruded aluminum bar can be attached directly to the top plate on the EGD-50. To attach the extruded aluminum bar, four ¼” bolts can be inserted through existing holes in the top plate and connected to T-nuts that can be inserted into the extruded aluminum bar. Top plate is designed for a 1.5” x 3” extrusion that has a 1.5” spacing between T-slots and a T-slot opening of 0.32”.

EGD-125 Options, Pictures & Drawings

EGD-125 Options, Pictures & Drawings

Optional, Quick Release Arm Arrangement:

To provide increased access to the press, this quick-release option allows the operator to simply lift the arm, (crossbar), off of the unit and to re-install the arm by simply placing it back on top of the unit. No tools are required to remove or replace the arm.

A: Alignment components slide into notches on angle brackets to assure the arm is correctly located on the unit.

B: Magnets hold arm between brackets

C: Angle brackets prevent the arm from moving Front to Back

EGD-125: T- Slot Type Mounting Brackets (PN: EGD-125-6099-0):

Brackets mount to the bottom of the EGD unit and can be fastened inside of T-slot. Standard brackets are based on a minimum bolster thickness of 4”, a distance of 23.62” to 24” between the mounting T-slots, and standard 1” T-Slots (brackets have a 1.75” wide x 0.75” thick bar that needs to be clamped into the bottom portion of the T-slot), and the edge of the bolster must be less than 6” from the end of the press bed.

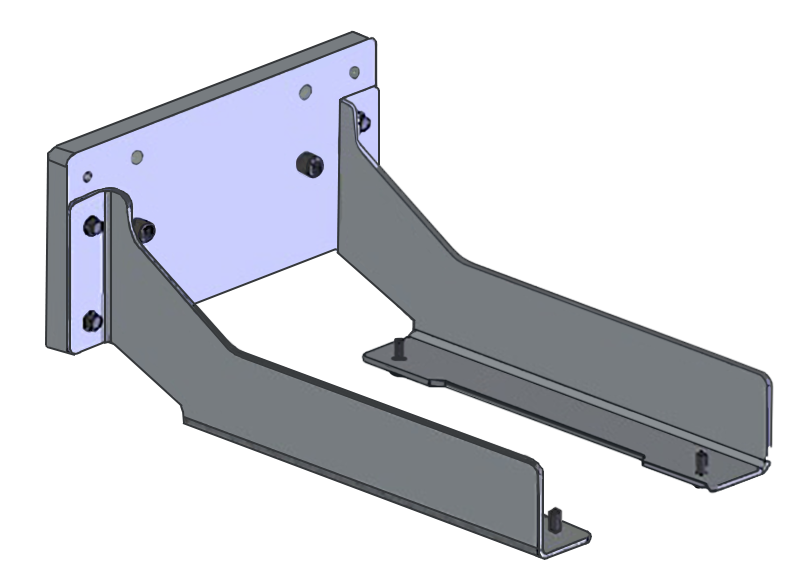

EGD-125: Shelf Type Bracket Model (PN: EGD-125-6098-0):

The shelf-type mounting bracket can be bolted to a vertical surface such as the press bed. After the bracket is properly attached, the EGD conveyor is bolted to the top of this bracket.

EGD-125: Vertical Face Mount Brackets:

These brackets are designed to bolt to the bottom of the EGD unit and to a vertical surface. The bracket design is based on the following:

- Each of the two brackets has two 0.53” diameter clearance holes for mounting bolts. These holes are located 3.25” apart.

- When brackets are mounted to the EGD conveyor, the total width of assembly is 26.7” and the distance between the mounting holes on the two brackets is 24.7”.

- Minimum height of mounting surface (bolster thickness) of 4.25”.

- Brackets will be painted black.

EGD-125: Floor Mount Brackets:

These brackets are designed to be bolted to the bottom of the EGD unit and then bolted to the floor.

- The width of the brackets is 28”.

- The diameter of clearance holes for floor anchors is 0.44”.

- The Center distance between the above clearance holes is 26”

- Distance from floor to bottom of the tray, (when the tray is parallel to the floor and does not have wear pads attached), is 9.9”.

EGD-125 Rolling Floor Stand:

Each stand (with the EGD unit attached) can be rolled up to the press and then fastened to the press’ T-slots.

Contact Pax for further information.

EGD-125 Adapter Plate for Extruded Aluminum Cross Bar:

For customers who have standardized extruded aluminum type cross bars, Pax can provide the EGD unit with an adapter plate designed for an extruded aluminum bar. This plate has two keys that are designed to fit into one of the extruded aluminum bar’s t-slots and it has four 0.32” clearance holes. Standard adapter plate is designed for a 1.5” x 3” extrusion that has a 1.5” spacing between T-slots and a T-slot opening of 0.32”.

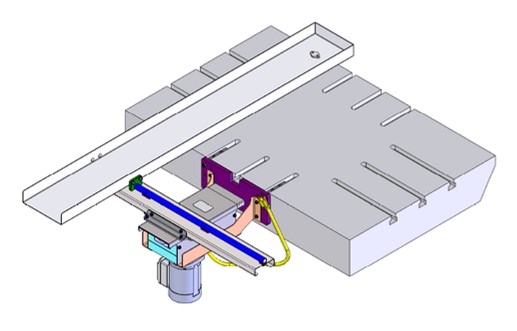

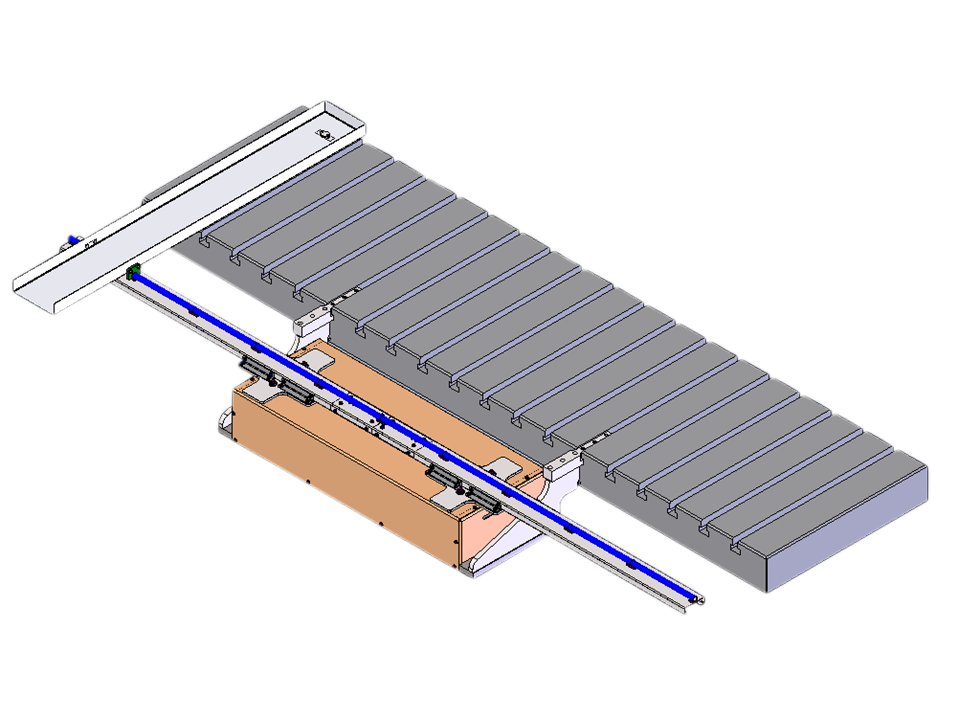

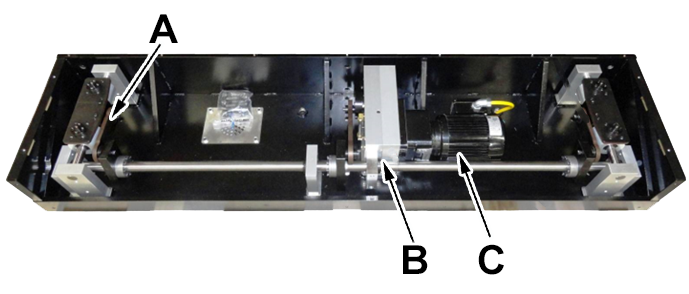

EGD-250 Options, Pictures & Drawings

EGD-250 Options, Pictures & Drawings

A: Guide Bearings are Widely Spaced and the Unit is Driven at Bearings, which resist off-center loading & maximize bearing life.

B: Elliptical Gear Drive in Sealed Oil Bath

C: Electric Motor

EGD-250-48 T- Slot Mounting Brackets:

Brackets are bolted to the conveyor base plate, are slid into the bolster T-slots, and large set screws are utilized to fasten the brackets in place. Once in place, bolts at the bottom of the bracket are extended outward until they push snugly against the bottom of the bolster, to increase the bracket’s support and reduce its vibration. Standard brackets are based on a bolster that is a minimum of 6” thick with standard 1” T-Slots and the brackets will mount into two separate T-slots that must be spaced 48” apart. Brackets are not available for the EGD-250-72.

EGD-250-48 Vertical Face Mounting Brackets:

Brackets are bolted to the conveyor base plate and are arranged to be bolted to a vertical surface (such as the face of a bolster plate). Brackets are not available for the EGD-250-72.

Option of Utilizing an Extruded Aluminum Cross Bar in Place of Pax’s Standard Cross Bar:

For customers who have standardized extruded aluminum type cross bars, the EGD-250 conveyors can be arranged for an extruded aluminum bar. The standard arrangement is for a 1.5” x 4.5” extrusion that has a 1.5” spacing between T-slots and a T-slot opening of 0.32”.

Trays and Tray Hardware

Trays and Tray Hardware

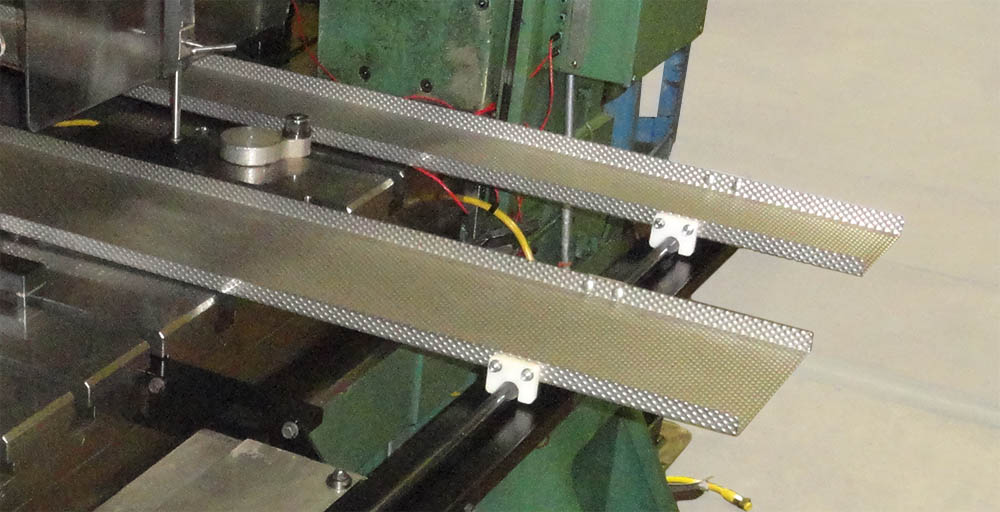

Conveyor Trays:

Pax can make shaker trays to your dimensions. Pax’s standard trays are made of 18 gauge, 304 rigidized stainless steel. Square mounting holes for carriage bolts for Pax’s quick-connect brackets and mounting holes for wear pads can be added to trays if locations are specified at the time of order.

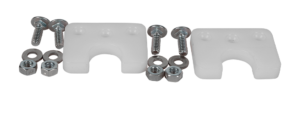

Quick Connect Tray Mounting Brackets

Brackets are utilized to mount customer-supplied trays to the standard Pax crossbar. After the brackets are properly mounted to the sides of a tray, the tray can then easily and quickly be snapped in place on the crossbar. Each set includes two (2) Acetal brackets (enough for one tray) and four ¼”-20 carriage bolts with nuts and washers. The customer must mount brackets to trays as required.

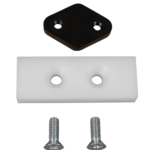

Bolt-On, Tray Wear Pad Kit (P/N EGD-000-6213-0):

This wear pad is typically used on trays in which the scrap is being conveyed toward the EGD unit. With this kit, the wear pad is placed on the bottom of the conveyor tray (typically towards the end of the tray) and is held in place with bolts that go through the pad and the tray and then thread into the nut plate that is positioned on the top of the tray. These pads raise the bottom of the tray by 0.5”. Kit includes; One, 3” long x 1” wide x 0.5” thick UHMW pad with two counter sunk drilled holes, two ¼” -20 flat head screws, and one “diamond” shaped nut plate.

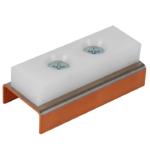

Weld On, Tray Wear Pad Kit, (Part #: EGD-000-6219-0):

This wear pad, which is welded to the bottom of the tray, is typically used on trays in which the scrap is being conveyed away from the EGD unit. With this kit, a bracket is welded to the bottom of the tray and the wear pad is then bolted to this bracket. This kit will raise the bottom of the tray by 1.06” (the bracket is 0.56” tall and the pad is 0.5” tall). Kit includes; One, 3” long x 1” wide x 0.5” thick UHMW pad with two counter sunk drilled holes, two ¼” -20 flat head screws, and bracket that has two tapped holes to which the wear pad is bolted.

Extensions for Tray Quick Connect Brackets:

These extensions are used to increase the height of the tray. The steel plates are attached to the tray and the tray quick-connect brackets are attached to the bottom of the plates. Each kit includes two steel plates, four carriage bolts, four washers, and four nuts for the carriage bolts. Kits are available in 1”, 2”, and 3” heights.

Tray Stop (PN EGD-000-6537):

These stops are typically used in cases where the quick connect tray brackets are prone to move on the crossbar, which can occur when the trays are not between parallels and/or a tray is irregularly shaped. The stops are designed to slide across the tube that is on the top of Pax’s standard cross. The stops can be locked in place on the tube by tightening the set screw on the top of the stop. Typically, two stops are used for each tray, (one on each side of the tray). Each of these stops is approximately 0.6” wide